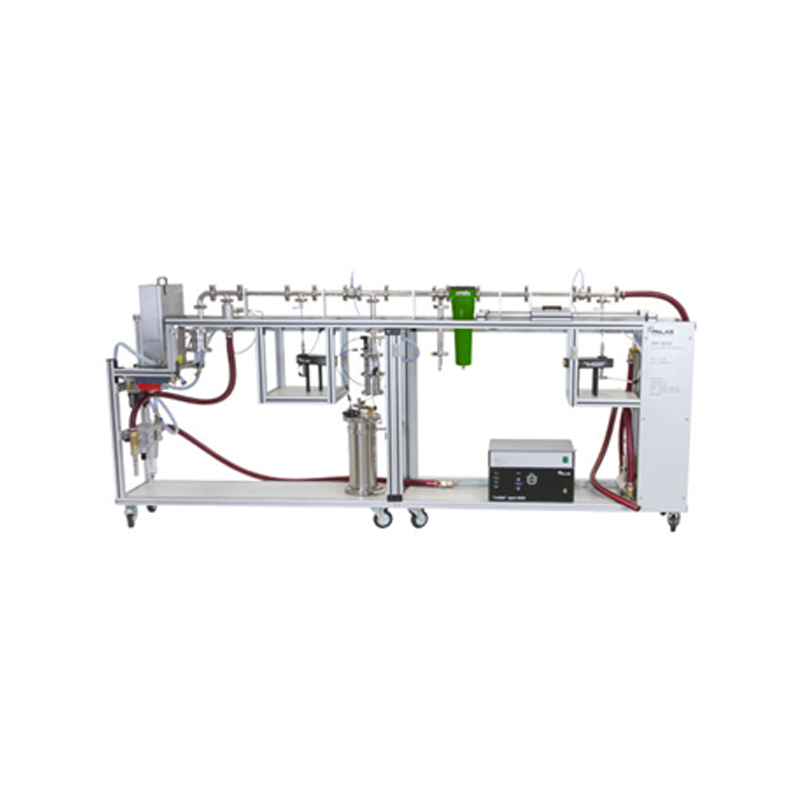

We have Filter test systems for the testing of cleanroom filters, motor vehicle passenger compartment filters, compressed air filters, oil separators, vacuum cleaner filters etc.

We can offer complete solutions for an extensive range of filter applications, whether at high temperatures up to 130 °C or pressures up to 10 bar. Our product range offers the world's largest selection of aerosol generators, dilution systems, and state-of-the-art particle measurement technology for particle sizes from 5 nm to 100 µm. These are modular, interchangeable individual components in the Palas test systems. Of course, existing testing conduits, e.g., in accordance with ISO 1690, Ashrae 52.2, or EN 779, can also be upgraded with Palas aerosol technology.

With this flexibility, testing requirements can be and reliably met to suit customer requirements to achieve compliance with the relevant standards.